Terminologies

- Product - individual Stockable Keeping Unit (SKU)

- Trackable Items - individual items within the Product. e.g. Apple has a product called MacBook Pro M1-MAX, and the organization has acquired two of this product from Apple. Each of the laptop is a trackable item.

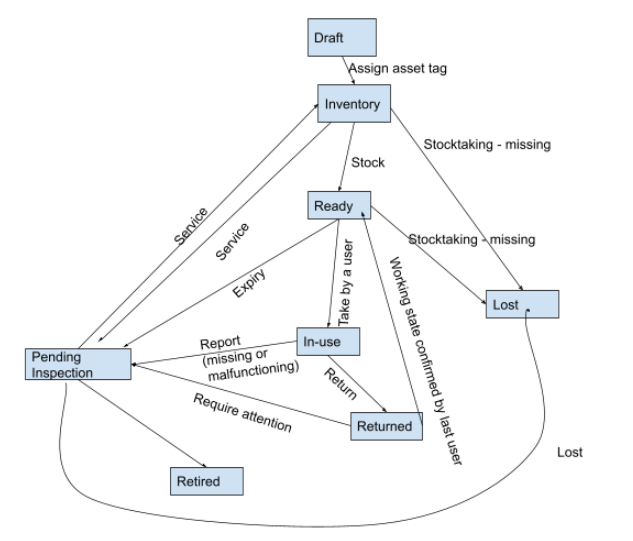

Trackable Item Lifecycle

Within PPE Vending system, a trackable item can be in one of the states,

- Draft - the trackable item does not have the asset tag yet.

- Inventory - the trackable item has an asset tag assigned (typically self-adhesive asset tag), but it’s not put into the vending machine, locker, or self-service shelf yet.

- Ready - the item has been deployed to the shelf or machine, ready to be taken by clients

- In-use - one customer has already taken the product

- Lost - the product has been confirmed to be lost during stocktaking

- Returned - the product has been marked as returned. This state is short, it will either automatically go to Pending Inspection, or Ready.

- Pending Inspection - the product requires attention from the asset manager. No one could use this product until the asset manager has made a decision.

- Retired - the product is decommissioned due to different reasons.

Trackable item attributes

Each of the trackable item has multiple attributes,

- Product (Category SKU) - which product does this trackable item belong to.

- Name - individual name for the trackable item.

- Asset Tag - the asset tag number that’s attached to the product.

Add Trackable Item

To add a trackable item into the database, please follow this procedure,

- Enable Trackable product

- Visit Trackable Items page

- Click Add button at the top

- Input Name of the trackable item

- Start typing in Product field, and select the product in the drop down menu

- Input in the Notes if necessary

- Click Save button to finalize the operation.

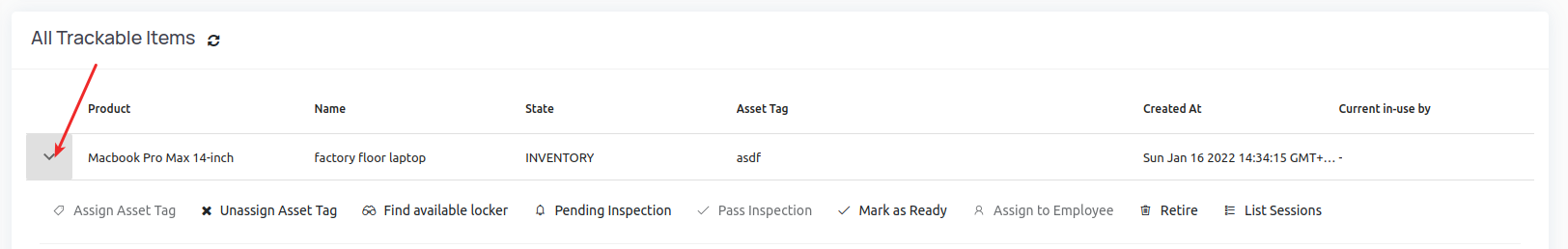

The newly created trackable item should be shown in the All Trackable items table below, and it should be in the Draft state.

Manage Inspection Reports

From time to time, a trackable item could be marked as “Require Inspection”, this could be due to

- Consumer reported a malfunctioning item.

- Consumer could not retrieve a product from the locker.

- The trackable item has finished its max uses between inspections.

In this situation, the administrators are required to

- Check the current session, talk to the current user

- Obtain the item physically and verify if it’s in working condition

- Perform necessary maintenance on the device

- Remove Pending Inspection mark and re-shelf the trackable item back to READY state.

All these operations can be done in the expandable row for each trackable item as shown below,

Use cases

Add a new item and make it available in locker

To add a new item and make it available in locker, please follow this procedure,

- Add a trackable item following steps specified in Add Trackable Item section. Now this item is in DRAFT state.

- Assign an asset tag to the trackable item in the operation drop down. Now this item is in INVENTORY state.

- Click Find available locker button to identify a locker cell for this item.

- Click Move here button to open the cell door, put the item in the cell. Now this item is in READY state.

And now this trackable item is ready to use.

Replace an item

To replace an item, there are a few steps,

- If the old item is still in the locker, mark the item as PENDING INSPECTION.

- Open the cell and remove the item.

- Click “Retire” button to deprecate the old item.

- Follow Add a new item and make it available in locker procedure to finalize the operation.

List units in use

To list all the units that are current in-use, please follow this procedure,

- Visit Trackable Items page

- Scroll down to All Trackable Items section

- Toggle Show in-use items only checkbox based on your requirement

Frequently Asked Questions

Q1: What are the different states a trackable item can be in?

According to the Trackable Item Lifecycle section, a trackable item can be in one of these states:

- Draft - the trackable item does not have the asset tag yet

- Inventory - the trackable item has an asset tag assigned (typically self-adhesive asset tag), but it’s not put into the vending machine, locker, or self-service shelf yet

- Ready - the item has been deployed to the shelf or machine, ready to be taken by clients

- In-use - one customer has already taken the product

- Lost - the product has been confirmed to be lost during stocktaking

- Returned - the product has been marked as returned. This state is short, it will either automatically go to Pending Inspection, or Ready

- Pending Inspection - the product requires attention from the asset manager. No one could use this product until the asset manager has made a decision

- Retired - the product is decommissioned due to different reasons

Q2: When does a trackable item require inspection?

The documentation states that a trackable item could be marked as “Require Inspection” due to:

- “Consumer reported a malfunctioning item”

- “Consumer could not retrieve a product from the locker”

- “The trackable item has finished its max uses between inspections”

When this happens, administrators must check the current session, talk to the current user, obtain the item physically, verify its working condition, perform necessary maintenance, and remove the Pending Inspection mark.

Q3: What’s the difference between Asset Tag and Name for a trackable item?

According to the trackable item attributes section:

- Asset Tag - “the asset tag number that’s attached to the product” (a physical identifier)

- Name - “individual name for the trackable item” (a descriptive identifier)

The asset tag is typically a self-adhesive label physically attached to the item, while the name is used for identification in the system.

Q4: How do I replace a trackable item that’s currently in use?

The documentation provides a specific procedure for replacing an item:

- “If the old item is still in the locker, mark the item as PENDING INSPECTION”

- “Open the cell and remove the item”

- “Click ‘Retire’ button to deprecate the old item”

- “Follow Add a new item and make it available in locker procedure to finalize the operation”

Q5: What’s the proper workflow for adding a new trackable item to a locker?

The documentation outlines this specific procedure:

- “Add a trackable item following steps specified in Add Trackable Item section. Now this item is in DRAFT state”

- “Assign an asset tag to the trackable item in the operation drop down. Now this item is in INVENTORY state”

- “Click Find available locker button to identify a locker cell for this item”

- “Click Move here button to open the cell door, put the item in the cell. Now this item is in READY state”

The documentation confirms “And now this trackable item is ready to use.”